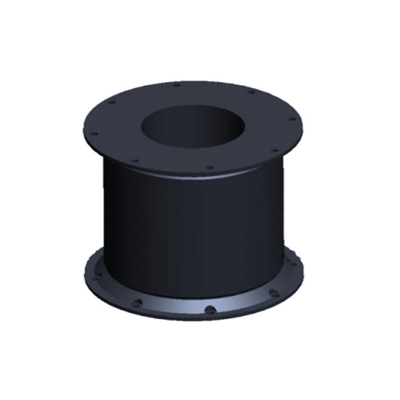

Rubber Dock Bumper High Pressure Tolerance Shock Absorption Tear Resistance

Description

Dock Rubber Fender for shipyard launching and construction operations is a highly specialized marine protection solution engineered to withstand extreme static loads, concentrated contact pressures, and complex dynamic forces generated during vessel launching, shifting, block assembly, and early-stage outfitting. Compared with conventional quay fenders used for routine berthing, shipyard dock rubber fenders are required to perform under significantly harsher conditions, including prolonged compression durations, uneven load distribution caused by hull curvature, and repeated micro-movements during construction operations.

Hongruntong Marine’s dock rubber fenders for shipyards are manufactured from reinforced natural rubber compounds with carefully controlled hardness gradients and high load-bearing capability. Through optimized formulation and molding processes, the rubber maintains stable elasticity while resisting creep and permanent deformation under long-term compression. The product range includes solid block fenders, cylindrical rubber fenders, laminated rubber pads, and customized composite structures. Dimensions, hardness, internal reinforcement layers, and surface profiles can all be tailored to specific launching methods such as slipway launching, skid launching, transverse launching, and floating-out operations.

By effectively absorbing impact energy, distributing contact loads, and reducing localized stress on hull plating and dock structures, these dock rubber fenders play a critical role in improving launching safety, protecting vessel coatings, and ensuring smooth construction workflows. They are widely adopted by commercial shipyards, offshore fabrication yards, and naval construction facilities where safety margins and repeatability are essential.

Case Study – Newbuild Chemical Tanker Launching and Reuse Program

A large-scale shipyard in Eastern China specializing in 30,000–50,000 DWT chemical tankers experienced recurring challenges during skid launching operations. As vessel sizes increased and construction schedules tightened, conventional timber and low-grade rubber supports resulted in uneven load transfer, localized hull coating damage, and excessive wear of temporary launching equipment. These issues not only increased repair costs but also introduced safety risks during critical launching stages.

Hongruntong Marine conducted a technical assessment of the launching arrangement, vessel weight distribution, and slipway geometry. Based on calculated static loads and friction forces, a set of customized dock rubber fenders was supplied, featuring increased contact surface area, higher compressive strength, and reinforced internal fabric layers. The rubber hardness was optimized to balance load support and elastic recovery.

During subsequent vessel launches, hull stress concentrations were significantly reduced, and coating damage was completely eliminated. Launching alignment improved, allowing smoother vessel movement and reduced manpower intervention. Most importantly, the dock rubber fenders demonstrated excellent reusability, remaining structurally intact after multiple launches. The shipyard reported over 25% reduction in launching-related maintenance costs and provided positive feedback regarding safety improvement and operational reliability.

Specifications

| Place of Origin |

China |

| Product Name |

Dock Rubber Fender |

| Type |

D Shape Type |

| Processing Service |

Compression Moulded |

| Color |

Black (More Colors Optional) |

| Material |

Smooth NR |

| Performance |

Excellent chemical and Physical Property |

| Logo |

Customer's Request |

| Application |

Port, Dock, Boat |

| Type |

Specifications |

| H |

B |

L |

Holes |

Q |

C |

h |

D |

d |

| D150x150x1000 |

150 |

150 |

1000 |

3 |

350 |

150 |

25 |

40 |

24 |

| D200x200x1000 |

200 |

200 |

1000 |

3 |

353 |

150 |

35 |

55 |

30 |

| D200x200x3000 |

200 |

200 |

3000 |

8 |

400 |

100 |

35 |

55 |

30 |

| D250x250x1000 |

250 |

250 |

1000 |

3 |

350 |

150 |

35 |

60 |

30 |

| D250x250x3000 |

250 |

250 |

3000 |

8 |

400 |

100 |

35 |

60 |

30 |

| D300x300x1000 |

300 |

300 |

1000 |

3 |

350 |

150 |

40 |

65 |

32 |

| D300x300x3000 |

300 |

300 |

3000 |

8 |

400 |

100 |

40 |

65 |

32 |

| D300x360x1000 |

300 |

360 |

1000 |

3 |

350 |

150 |

40 |

65 |

32 |

| D300x360x3000 |

300 |

360 |

3000 |

8 |

400 |

100 |

40 |

65 |

40 |

| D400x400x1000 |

400 |

400 |

1000 |

3 |

400 |

150 |

55 |

80 |

32 |

| D400x400x3000 |

400 |

400 |

3000 |

8 |

400 |

100 |

55 |

80 |

40 |

| D500x500x1000 |

500 |

500 |

1000 |

3 |

350 |

150 |

90 |

97 |

45 |

| D500x500x3000 |

500 |

500 |

3000 |

8 |

400 |

100 |

90 |

97 |

45 |

| TECHNICAL DATA |

| PROPERTIES |

TEST STANDARD |

VALUES |

| Compound |

- |

NR / SBR |

| Density (Specific Gravity) |

DIN 53505 |

1200 kg/m3 |

| Tensile Strength |

DIN 53504 |

≥16 MPa |

| Elongation at Break |

DIN 53504 |

≥350% |

| Tear Resistance (23°C) |

DIN 53507 |

≥80 N/cm |

| Abrasion Resistance |

DIN 53516 |

≤100mm3 |

| Compression Set (24hrs @ 70°C) |

DIN 53517 |

≤40% |

| Ozone Resistance (ppm 20% 72hrs @ 40°C) |

ISO 143/1 |

No Cracking Visible By Eye |

| Change In Hardness |

DIN 53504 |

≤5° |

| Change In Tensile Strength |

DIN 53504 |

≥80% |

| Change In Elongation at Break |

DIN 53504 |

≥80% |

| Minimum Temperature |

- |

-30°C |

| Maximum Temperature |

- |

+70°C |

Features

Superior Energy Absorption and Reaction Force Characteristics

At the core of our Dock Rubber Fender's performance is its meticulously calibrated elastomer compound and internal structure. Unlike generic rubber products, our fenders are engineered to provide an optimal balance between high energy absorption (measured in kNm) and appropriate reaction force (measured in kN). This means they can dissipate the immense kinetic energy of a berthing vessel efficiently while exerting a controlled, manageable force back against the hull. This is achieved through precise rubber hardness (Shore A) grading and, in larger units, strategic incorporation of internal plate or fiber reinforcement. This technical characteristic is crucial for protecting both fragile ship hulls (e.g., painted cruise ships) and rigid concrete docks, as it minimizes peak pressure points that cause crushing or cracking.

Exceptional Durability and Environmental Resistance

We utilize advanced polymer formulations—typically nitrile rubber for excellent oil resistance and toughness, or EPDM for superior weather and ozone resistance. Each compound is fortified with anti-aging agents, UV stabilizers, and antioxidants. This results in a fender that withstands prolonged exposure to saltwater, temperature extremes from -40°C to +60°C, solar radiation, and atmospheric ozone without significant degradation in elasticity or surface cracking. The outer skin is specifically designed for high abrasion resistance against rough hull surfaces and repeated compression cycles, ensuring a service life often exceeding 15-20 years even in high-traffic ports, dramatically reducing the total cost of ownership.

Low Maintenance and Easy Installation Design

Hongruntong fenders are designed for practicality throughout their lifecycle. They are manufactured as single, robust units or in modular sections for larger sizes, simplifying transport and handling. Pre-molded fixing holes or integrated steel frames (for some types) allow for straightforward bolting or welding to pre-installed dock panels or chains. Their non-corrosive rubber construction eliminates the need for painting or cathodic protection required by steel fenders. Inspection is visual and simple; there are no internal hydraulic fluids to leak or mechanical parts to seize. Routine maintenance is typically limited to checking fastener tightness and clearing debris, leading to minimal operational disruption.

Versatility through Custom Engineering Support

While we offer a wide array of standard fenders, our core strength lies in providing tailored solutions. Our engineering team can modify standard designs or create entirely custom profiles to meet unique challenges: unusual berthing angles, specific energy absorption curves, extreme low-temperature applications, or integration with existing fender panels. This collaborative design process ensures the delivered product is not just an "off-the-shelf" item but a precision-engineered component of your marine infrastructure.

Applications

Commercial Shipping Ports and Terminals

Essential for container terminals, bulk cargo wharves, and RO-RO facilities where daily berthing of large vessels demands reliable, high-capacity protection to maintain throughput and avoid costly damage.

Shipyard and Dry Dock Applications

Used to guide and cushion vessels during the critical processes of docking and undocking in repair facilities, protecting the ship's hull and the sensitive dock walls and blocks from impact.

Ferry and Passenger Terminals

Prioritizes passenger comfort and safety by providing smooth, low-impact berthing, while also protecting often more aesthetically sensitive terminal structures.

Why Choose Hongruntong Marine

Proven Expertise and Technical Consultation

Hongruntong Marine is not merely a manufacturer; we are a solutions provider backed by decades of specialized maritime engineering experience. Our team engages from the project's inception, offering comprehensive technical consultations. We perform detailed berthing energy calculations, analyze site-specific conditions (tides, currents, vessel types), and recommend the most efficient fender type and layout. This consultative approach ensures our clients receive an optimized system, not just a product, maximizing their investment's effectiveness and longevity.

Stringent Quality Control and Material Science Leadership

Quality is engineered into every fender from the raw material stage. We source premium raw polymers and conduct rigorous incoming material testing. Our proprietary compounding recipes are developed in-house and mixed under controlled conditions to ensure batch-to-b consistency. Every production batch undergoes a battery of tests, including hardness, tensile strength, elongation, tear resistance, and compression set, often surpassing ISO 9001 and relevant marine fender standards (e.g., PIANC guidelines). This commitment to material science guarantees that every Hongruntong fender delivers its promised performance metrics consistently.

End to End Project Management and Logistics Support

We manage your order as a complete project. From design finalization and production scheduling to packaging, shipping, and delivery documentation, our dedicated project coordinators ensure a seamless process. We are experienced in handling complex international logistics, including containerization and break-bulk shipments to remote job sites, ensuring your fenders arrive on schedule and in perfect condition, ready for installation.

Comprehensive After Sales Support and Warranty Commitment

Our relationship with clients extends far beyond delivery. We provide detailed installation guidance and are available for technical support during the installation phase. Each product is backed by a strong warranty that covers defects in materials and workmanship. Furthermore, we offer long-term support for inspection guidance and can supply replacement or complementary units as your infrastructure expands or requires maintenance, ensuring you have a reliable partner for the long haul.

FAQ

1. What standards do Hongruntong Dock Rubber Fenders comply with?

Our fenders are designed and manufactured in accordance with major international standards, including PIANC (World Association for Waterborne Transport Infrastructure) guidelines for fender design, ISO 9001 for quality management systems, and relevant parts of ASTM standards for rubber physical testing. Specific certifications can be provided upon request.

2. How do I select the correct fender size and type for my dock?

Selection requires analysis of key parameters: the berthing energy of the design vessel (based on displacement, velocity, and berthing angle), the tidal range, the structure's allowable reaction force, and the hull pressure limit. We strongly recommend consulting our engineering team. We can perform this analysis for you using your project data to recommend the optimal fender.

3. Can your fenders be used in extremely cold or hot climates?

Yes. By selecting the appropriate polymer compound (e.g., special low-temperature modified rubber or EPDM), we can manufacture fenders suitable for a wide operational temperature range from as low as -50°C to as high as +70°C without significant loss of elasticity or performance.

4. Are the fenders easy to install on an existing dock structure?

Absolutely. Our fenders are designed for straightforward retrofit. They typically come with pre-drilled fixing holes or integrated attachment systems. Installation usually involves bolting to pre-welded back plates or connecting to chains. We provide detailed installation drawings and manuals for guidance.

5. What is the expected service life of a rubber fender?

Under normal service conditions, Hongruntong Dock Rubber Fenders have an expected service life of 15 to 25 years. The actual lifespan depends on factors like frequency of use, severity of impacts, exposure to sunlight/oil, and water quality. Regular visual inspection for deep cuts or significant deformation is recommended.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!